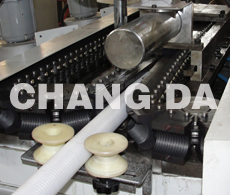

Production line Introduction

The machine mainly produces various caliber single wall corrugated tubes with PP, PE and PVC as raw materials.;

Through the corresponding mold, forming a smooth, corrugated bellows to the product;

Corrugated pipe production line to configure single/twin screw extruder, pipe bellows forming machine, tire mold, air cooling apparatus, counters, winding machine, continuous extrusion diameter corrugated pipe sizes-standard;

Reasonable structural design of special screws, moulds, mould replacement is convenient and reliable, solution to the screw and barrel are easy to wear and the problems of material forming, high speed, stable running, control is simple and easy to operate.

Bellows forming machine for closed construction, and provide vacuum forming.Closed molding molding module in a whole movement in the tunnel, forming a tunnel designed for mezzanine, by uniform cooling of cooling modules, molded modules without local connections, so agreed to shorten the time replacing.High production speed, cooling quickly;

The equipment to produce tubes, high temperature resistance, corrosion resistance, wear resistance, high strength.Electric pipe threading, auto Threading pipe, jacket tube, machine tools, packaging machinery, electric locomotive, instrumentation engineering, installation, lighting, automation and other fields, and market de

Technical parameters

|

Production line Model

|

/mm

Pipe diameter

|

Extruder model

|

/m

Traction speed

|

/kw

Total installed capacity

|

/m

Length

|

|

CDH-SCP10

|

4-10mm

|

SJ30

|

1-12m

|

12kw

|

7m

|

|

CDH-SCP32

|

12-32mm

|

SJ45

|

1-10m

|

28kw

|

10m

|

|

CDH-SCP90

|

40-90mm

|

SJ65

|

1-6m

|

53kw

|

16m

|

|

CDH-SCP200

|

110-200mm

|

SJ90

|

1-3m

|

88kw

|

20m

|

|

CDH-SCP300

|

160-300mm

|

SJ120

|

0.5-2m

|

130kw

|

26m

|

|